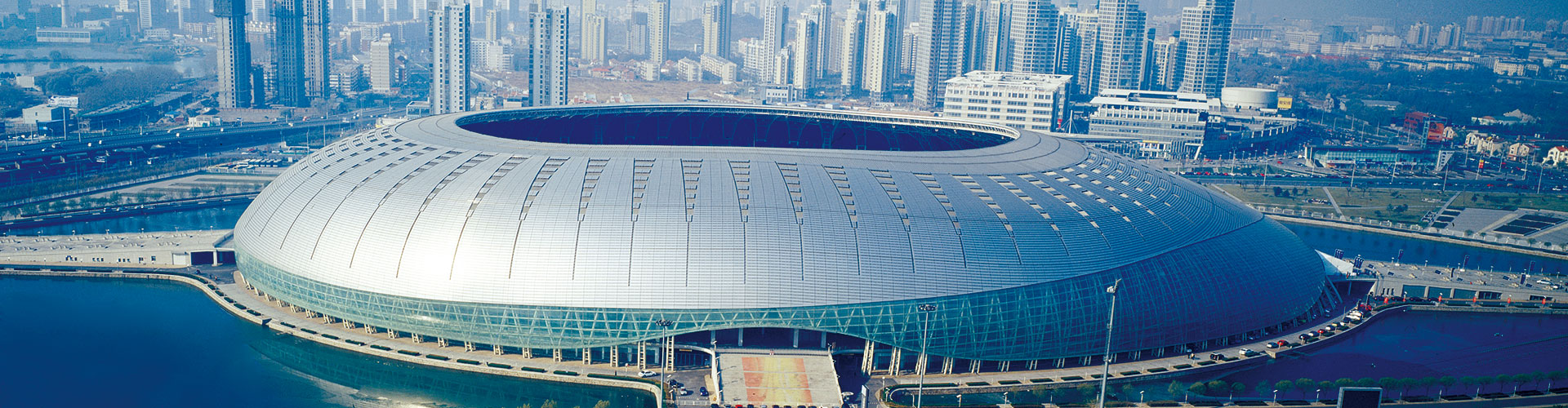

It refers to the building roof protection system adopts metal sheet as sheet materials. Its supporting system is mainly metal frame, such as steel, aluminum alloy frame, etc. The metal sheet using as sheet materials can be aluminum alloy sheet, Titanium-Zinc sheet, pre-casting steel sheet or aluminum sheet (“seam standing panel”), etc. Metal roof can be divided into the following catalogs by sheet materials and structure: panel metal Roof, seam standing panel metal roof and composite metal roof, etc. Metal roof of various types can be applied to many roof shapes including complex curve shape. The proper choosing and configuration of building metal roof should be based on building appearance, requirements of functions and physical performance as well as technical features of metal roof. The various metal roof systems which are researched independently by Yuanda and generally applied to the projects have the following common technical features:

●Light overall weight of metal roof compared with traditional concrete roof to reduce bearing load of main structure.

●Good movement absorbing capacity and is adjustable for distortion and movement caused by temperature change and earthquake.

●Easy installation and lower cleaning and maintenance cost.

●Fast installation to reduce construction period

●Recyclable and environmental friendly material is used.

Additionally, each type of metal roof has its own outstanding technical features:

Panel Metal Roof

It is the metal roof adopts metal panels (aluminum sheet, steel sheet, Titanium-Zinc sheet, etc.) as its sheet materials.

●PVDF coating finish is used to achieve high anti-corrosion and anti-aging performance. Various colors, metallic effect and consistent color retaining capacity will bring perfect building shape and visual artistic effect.

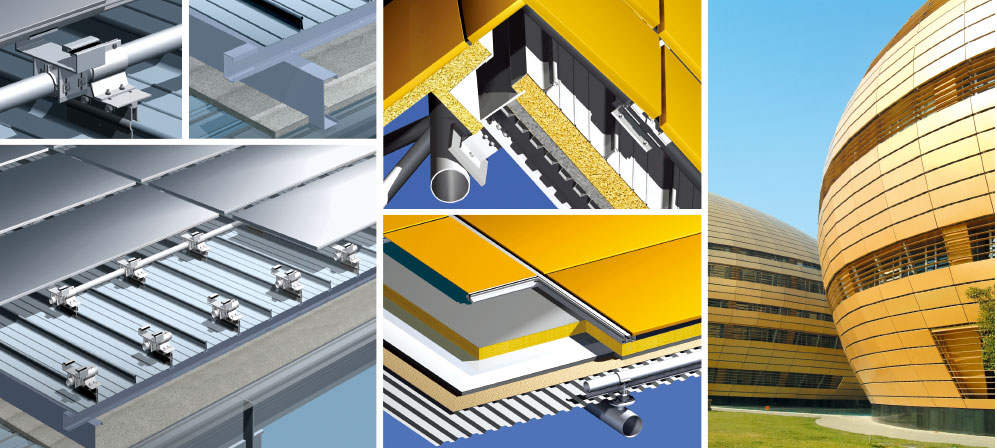

●System structure is similar to structural member type concealed frame curtain wall, and aluminum alloy sub frame is attached at the perimeter of metal panel which is connected to the supporting keel by a flexible and floating connection to achieve good movement absorption capacity.

●Weather proof silicone sealant is used in panel joints sealing, and sealing sealant size will be calculated based on maximum movement condition in practical condition. Under the situation of maximum panel movement, sealant joint will not crack and can maintain good sealing capacity.

●Double sealing inside and outside, and also inner drainage access is set. Dual secured design will ensure water proof performance of metal roof.

●Establish 3D model assisted by computer to complete complex curved design and instruct fabrication, site set-out and installation.

●Metal panel is fabricated by imported high-precision equipment to achieve the high flexibility, plasticity and complex curve.

Seam Standing Metal Roof

It is the metal roof adopts aluminum-magnesium-manganese alloy sheet as its sheet materials which is of high anti-corrosion capacity and long service life.

●Seam standing panel can be fabricated into rectangular, trapezoid (sector), etc. to form required plan slop, single curve, double curve and other complicated curves to meet metal roof shaping requirements.

●Seam standing connection is used for panels to form structural waterproof, and edge locking operation is applied by special machine to create reliable sealing and waterproof performance.

●Perfect structure of edge sealing and jointing ensure sealing and waterproof performance.

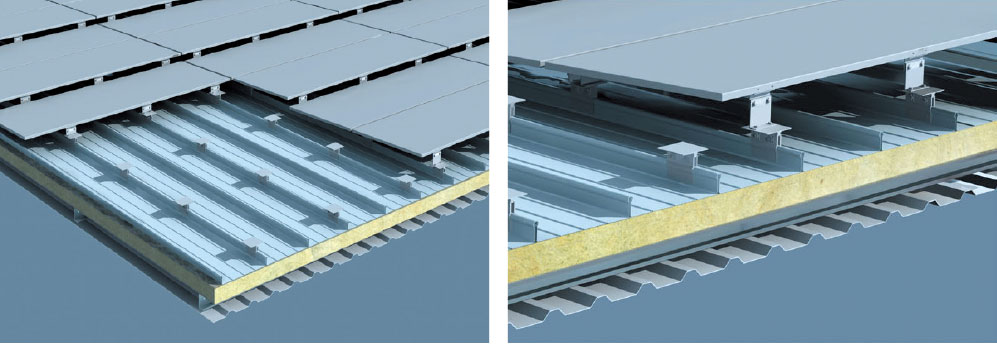

●Floating connection is used between sheet and supporting keel, and this connection will absorb temperature distortion and movement of building by slipping between sheet and supporting. The system has a mature technique and stable performance.

●Special software is used to make U-value analysis and instruct U-value design, so as to create excellent thermal insulation performance of system.

●All insulation and waterproof adopt non-inflammable or flame retardant material to achieve fireproof. Construction fireproof should be considered for system design and material selection.

●Proper system structural design and material selection will achieve good sound reduction and sound absorbing performance of metal roof and prevent rain noise of roof panel and sound transferring indoor and outdoor.

●Material of roof panel is rolled on site by equipment, and line production and integrated installation are used in processing of profiling-installation-edge locking, by which efficient construction and reliable construction quality are achieved.

Multiplex Metal Roof

Composite metal roof is double-layer metal roof, which usually adopts panel metal roof of good decorative function as outer roof structure, and seam standing panel metal roof of reliable waterproof performance as inner roof structure. The followings are main technical characteristics of composite metal roof:

●Outer metal panel roof has a perfect decorative function with various colors and metallic effect. Meanwhile, as the inner roof has reliable waterproof performance, the outer metal panel can be made into open system with no sealant applied at joints to avoid panel contamination by sealant, by which it can achieve neat and clean surface to strengthen decorative performance.

●Outer layer roof panel is fixed in the seam standing of inner system by clamping bracket and this setting will not cause damage to inner sealing and make inner and outer metal panels to be independent. Under temperature and structural deflection effect, no distortion or damage will occur to impact on system performance.

●Natural flow air in the air chamber between inner and outer metal panels makes better insulation and acoustic performance of metal roof.

●Simple and convenient installation, suitable technique and reliable construction quality.

●Easy to maintain, replace and clean.