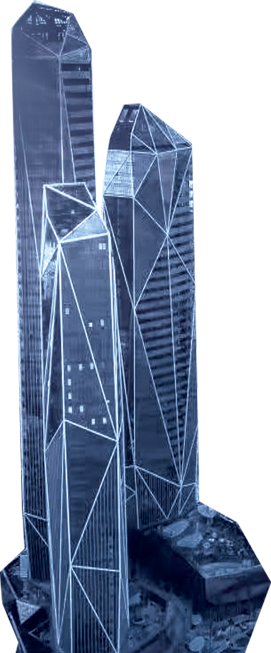

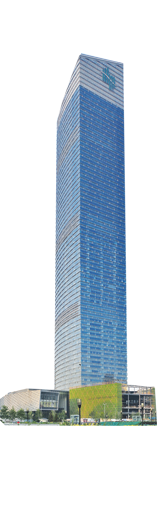

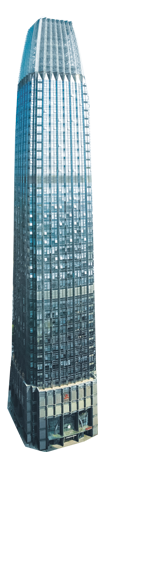

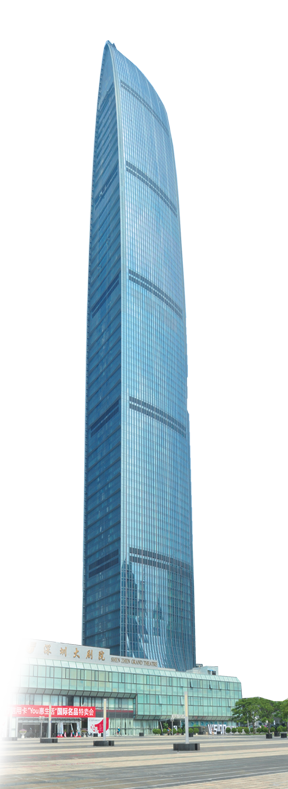

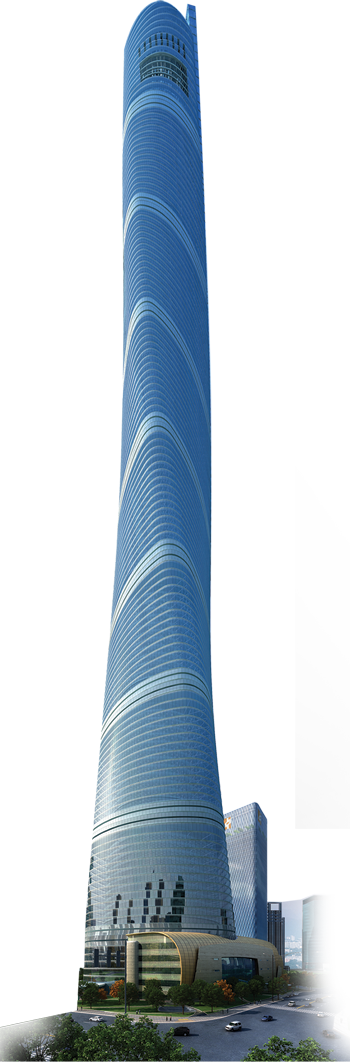

Project : PINGAN IFC

Location: Lot 1,Zhongxin District Shenzhen City.

Construction Company:

China Ping An Life Insurance Company Limited

Building Height: 592m

Floor Area: 460,665m2

Area of Curtain Wall: 174,316 m2

Curtain Wall Type: unitized glass curtain wall, unitized stainless steel curtain wall, unitized stone curtain wall ,semi-unitized glass curtain wall, semi-unitized stainless steel curtain wall, steel canopy.

Architecture Design Institute: KPF USA, CCDI (SHEN ZHEN)

Architect(s): David Malott (KPF), Xie Fang( China state international)

Curtain Wall Consultant: ALT Classding & Design

Consultant: Chen Zhikang

Main Contractor: China State 1 Bureau (Group) Limited.

Project Supervisor: Shanghai Construction Supervision Co.,Ltd

Quantity Surveyor:LIBI limited

Materials:Aluminum profile from Foshan JMA; CSG China glass,8mm heat strengthened ultra white+1.52PVB+8mm heat strengthened ultra white LOW-E+12A+12mm fully tempered ultra insulating laminated glass,10mm heat strengthened ultra white+1.52PVB+10mm heat strengthened ultra white+12AS+10mm heat strengthened ultra white+1.52PVB+10mm heat strengthened ultra white insulating laminated glass,12mm heat strengthened ultra white+1.52SGP+12mm heat strengthened ultra white+1.52SGP+12mm heat strengthened ultra white laminated glass,15mm fully tempered+1.52SGP+15mm fully tempered ultra white laminated glass,6mm heat strengthened ultra white+1.52PVB+6mm heat strengthened ultra white laminated glass,19mm tempered ultra white glass,6mm heat strengthened ultra white+1.52PVB+6mm heat strengthened ultra white laminated glass,19mm tempered ultra white glass , Hongkong victory 3mm PVDF coating aluminum panel, imported 2mm wove stanless steel panel,1.5mm stainless steel panel,0.8mm wove stainless panel, imported granite.

https://yuandacn.com/index.php/en/projects-cn-2/120-domestic/guangdong/211-pingan-ifc-2.html#sigProId894a5dea53

PINGAN IFC tower with diamond-shaped is located in the center of Shenzhen City. It is the tallest building in china, a complex high-rise building serving for super Grade A office, 5-star hotel, fashion shopping, culture entertainment and tourism. Construction height is 592.5 meters with 5 floors underground, tower roof is 588 meters, height of 115 floor is 538 meters. The curtain wall system is including unitized glass curtain wall, unitized stainless steel curtain wall, unitized stone curtain wall, semi-unitized glass curtain wall, semi-unitized stainless steel curtain wall, steel canopy etc. Area of curtain wall is 174316m2, 15876 panels,12 curtain wall system. A complex geometry view, difficult construction and high performance requirements inclined from 1-35 floors, the main facade slopes downward with tilt angle of 2 ° 42 ‘, vertical is from 35-97 floors , inclined from 97-118 floors ,the main facade of the upward tilt with angle of 23 ° 16 ‘; 118 floor is for sightseeing, above 597 meters is for the top of the tower,

Characteristics of the project

Application of new materials: 2mm cloth25 "stainless steel plate

The cloth stainless steel is to be used in most areas of this project, area is approximately 83,650 m2, which is located in the big triangle plate (T1 system) . The standard giant column cladding is from 131.8 to 570.9 m (T8 system), as well as the more angular sizes and side finishing by the stainless steel surface material and more folding angles. Due to the characteristics of cloth stainless steel, the process should be embossing first, folding second, strict requirements on design fabrication and surface treatment. For this feature, the panel at the hem should be grooving first when designing the stainless steel in order to folding easily without affecting the surface effect. Also, the strength of the surface will be affected because of the grooving. So, it should be arranging aluminum alloy rib for strengthening the surface material.

https://yuandacn.com/index.php/en/projects-cn-2/120-domestic/guangdong/211-pingan-ifc-2.html#sigProIdb7b294e1f9

The design of the tower crown conversion layers

The tower crown location is the conversion between the unitized curtain wall and the component curtain wall, the conversion of two types of curtain wall using by inverted triangle .The difficulty in design and construction is high. It is to be considered that the panels for this part can be pumping when design as well as considering the convenience of the installation. The installation of this part of the curtain wall connection, it should be scaffolding at 115 floors to install the 116 component glass curtain wall ,Preserving for triangle glass from the ceiling which is not installed, laying corrugated steel for plugging gaps in the triangle to prevent falling objects, subsequently , setting up hoist in the room No.116.

The sling is hanging from the ceiling at the triangular glass, to install the floor 115 panel, the ceiling glass panel to be installed indoor at last.

The panel are lifted indoor by crane through the triangular hole, and then lift the panel to the top, connecting with the components. The people is requiring to operate panel on the hoist indoor.

Application of super high-rise stone

The tower columns under 131.8m are adopting 50mm seaweed green stone, which is a super high-rise stone, brittle materials, designing to increase the stone protective net, stone anti-drop hook and safety.

https://yuandacn.com/index.php/en/projects-cn-2/120-domestic/guangdong/211-pingan-ifc-2.html#sigProId08566120cd

BIM technology Application Note

For this project, our company will adopt but not limited to the following software such as AUTODESK REVIT,INVENTOR,NAVISWORKS,RHINO and GRASSHOPPER,CATIA. To create BIM model and using BIM models to serve in this project.

With an application of building information modeling, it can support the continuous application of the various projects and timely applications. Also these information is to be used with high quality, reliability, integration and coordination, to improve greatly the quality and efficiency of the design and the whole project, reducing the cost at the same time.

PINGAN IFC is a landmark high-rise building in Shenzhen, BIM system is to be used from project planning, design and construction to the whole process of handover operational application, to adopt the consistent data platform; it will lead to improve significantly the effectiveness of the coordination between the design and the construction division, to reduce the risk of mistake, drain, touch implement process, so as to promote the optimization of the whole project construction and greatly leading role in the construction industry in China.

Application of BIM system in all aspects of PINGAN IFC project, will be able to:

※use the functions of the model of cost control, evaluate on design and construction;

※obtain the lower cost and risk for the owners, design and construction.

※because of the visual design, effectively monitor in order to assist reducing operating cost;

※resolve a variety of collision conflict before construction;

※because of visualization, the good design recommendation be easily understood by each party.

※for project management, create a four-dimensional schedule, to optimize the construction sequence.

※clear all the working interface using by 3D and 4D models , eliminat the ambiguity.